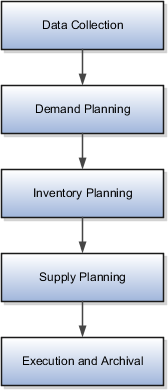

Oracle Fusion Planning Central business flows.

- Process data collection, demand planning, inventory planning, and supply planning.

If you choose Demand and Supply as the plan type, Demand planning, Inventory planning and Supply planning can be a single step.

- Automate the entire sequence of planning processes or run a subset of the processes.

- Analyze and adjust your data at any stage.

Data Collection

Data collection is the first step of the planning business flow. You can collect and transform the data from various Oracle Supply Chain Management cloud applications to the Planning Central schema.

The data that you collect can be of three types:

- Master data: Primarily sourced from Oracle Supply Chain Management cloud.

- Demand data: Two potential sources of demand data are sales orders that flow from the Oracle Order Management cloud and the shipment history from the Oracle Materials Management cloud.

- Supply data: The supply data

are collected from three sources:

- Oracle Inventory Management cloud

- Oracle Manufacturing cloud

- Oracle Purchasing cloud

Demand Planning

Using demand plans you can run the statistical forecasting processes to generate demand projections. You can also compare the statistical forecasts with sales forecasts.

Planning Central’s forecasting engine supports the following forecasting methods:

- Holt

- Regression

- Transformation Model (Log)

- Regression for Intermittent

- Croston for Intermittent

- Modified Ridge Regression

Planning Central’s forecasting can handle many common demand planning requirements, including:

- Forecast bookings and shipments based on historical demand.

- Provide accuracy metrics.

- Generate inputs to safety stock calculation for regular and sparse demands.

- Cleanse data (remove leading zeroes, fill in missing values, and remove outliers).

- Forecast new items.

- Sanity checking (load forecasts from an external system and compare with the Planning Central statistical forecast).

Inventory Planning

You can use inventory planning capability to calculate statistical safety stock based on the volatility of demand and stocking targets. It addresses diverse supply and demand patterns with multiple algorithms based on Mean absolute deviation in units (MAD), Mean absolute percentage error (MAPE) and arrival rate. Target service levels may be set at any dimension of the hierarchy, allowing you to segment your stocking policies by customer, channel, product family, warehouse, or other factors. Inventory can also be set manually by using mass updates when appropriate, such as when launching a product.

Supply Planning

Using supply planning you can calculate resource and material requirements based on customer and safety stock requirements, lead times, calendars, availability, and other parameters.

You can generate unconstrained supply plans, meaning that you ignore limited resource or supplier capacity, which provides the following advantages:

- Balances supply and demand and recommends new supplies as needed.

- Recommends when to reschedule or cancel a supply.

- Identifies material shortages, resource overloads, and supplier capacity overloads.

- Identifies when supplies don’t have sufficient lead time (lead time compression).

- Plans your entire supply chain, including contract manufacturers.

Supply plans can model outsourced manufacturing and delivery scenarios, including drop ship and back-to-back orders. It also supports hub and spoke planning configurations, such as using an MPS plan as a demand schedule to an MRP plan.

Demand and Supply Planning

Planning Central brings together the key functional requirements of demand management, inventory planning, and supply planning to a single platform and then links the planning processes to execution systems.

Using a demand and supply planning processes you can do the following:

- Generate demand forecasts and consume against actual sales orders.

- Calculate statistical safety stock requirements.

- Plan supply (work orders, material transfers, and purchases) to fulfill demand and manage inventory.

- Release planned orders for execution.

Plan Execution

You can share the order recommendations and save the plan to drive execution.

By default, Planning Central is integrated with other Oracle SCM cloud application. During the plan execution, the integration helps in the following:

- Automatically releases planned orders and reschedules of existing supplies.

- Manually releases groups of orders when necessary.

- Manages changes and cancellations.

- Manage back-to-back and drop ship orders.

Planners can set up automatic release rules or release orders manually

Complete end to end Oracle Fusion Planning Central Videos are available @best price.With this Planning central realtime demo BR100 will be provided

Please contact-job.mytechnojournal.com or ping @8917478413

Also subscribe to our youtube channel below